12

Produkte

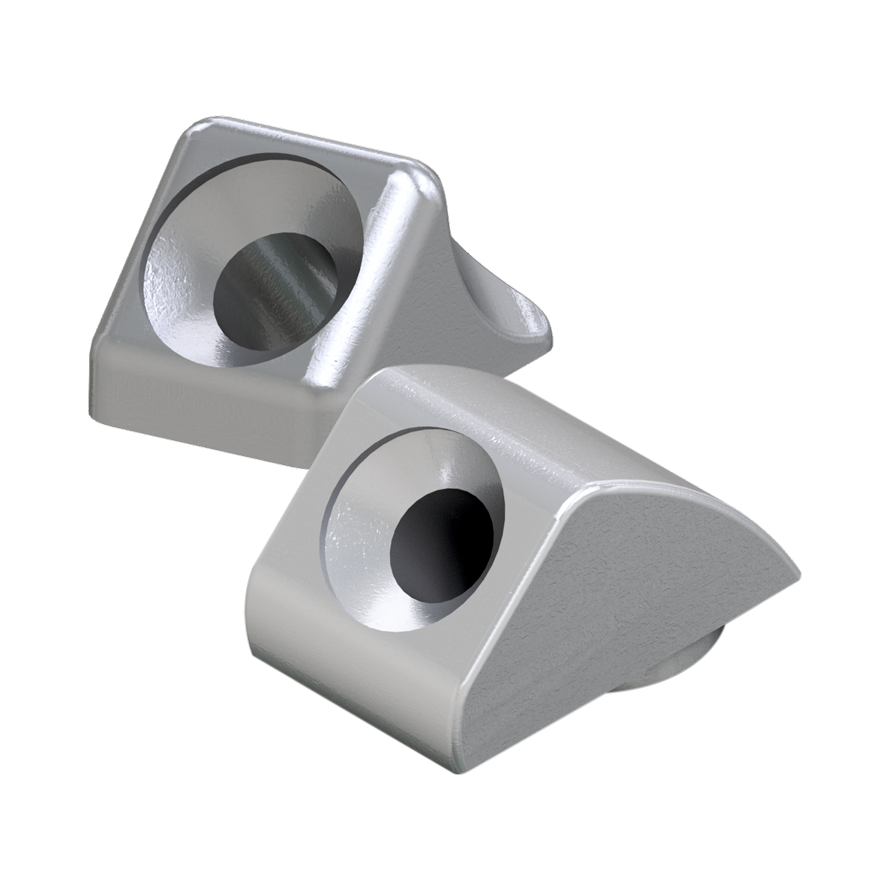

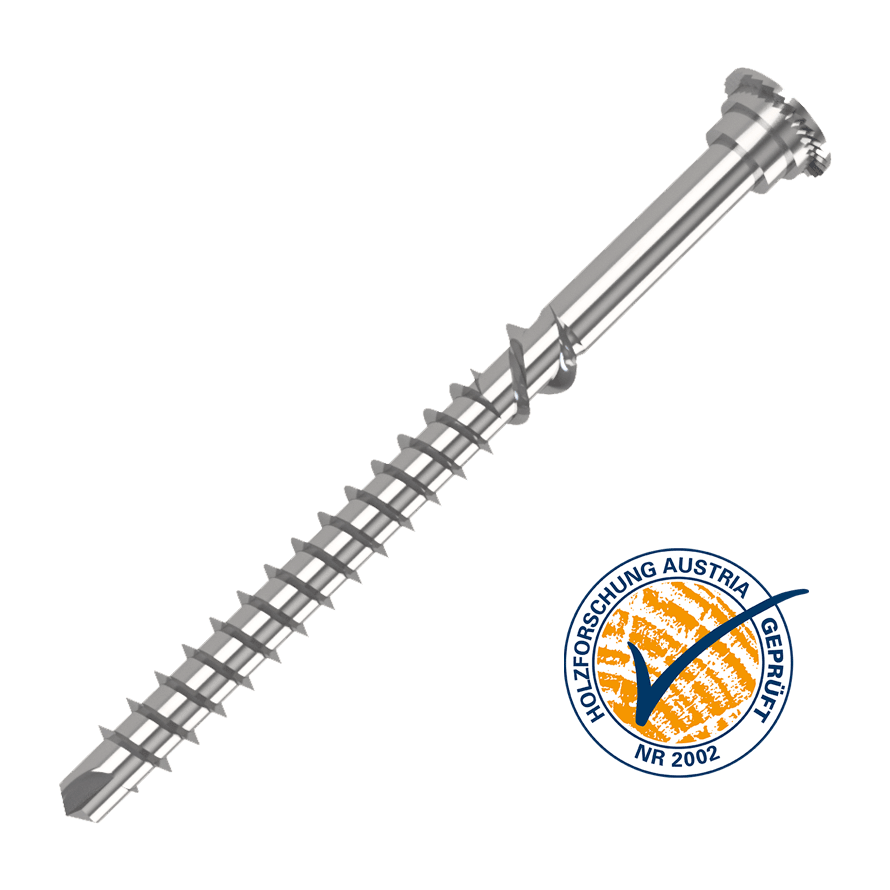

L-GoFix® MS

fastens wood to wood without pre-drilling and without countersinking Hardened stainless steel (C1) and stainless steel (A2). Please note when selecting!

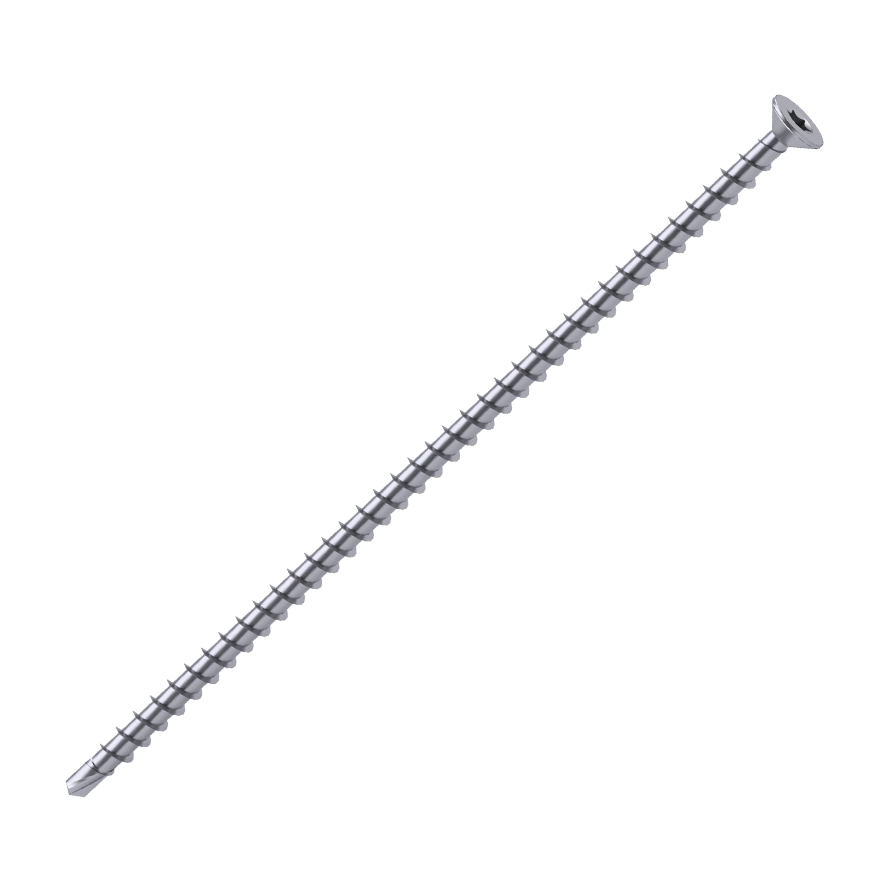

TeFix®

made of hardened

stainless steel. Fastens wood to wood without pre-drilling and countersinking.

Easy-to-process system screws from SIHGA®

SIHGA® system screws are high-quality screws for timber construction. They are renowned for their high load-bearing capacity and their long service life and are therefore particularly suitable for terrace construction, facade construction as well as for the construction of fences, carports, roof structures, solid wood construction, timber frame construction and other applications where fast and reliable assembly is required.

The special shape of the system screws ensures that the screws sit firmly without any risk of slipping, even under heavy loads. All in all, SIHGA® system screws provide a secure and reliable connection for wood and wood composite materials such as decking boards, fence posts, rafters or other structures. But SIHGA® also offers the right screws for metal such as aluminium or steel. Both the fully threaded and the partially threaded and the double-threaded screws are particularly robust and durable and can therefore be used for applications with high loads.

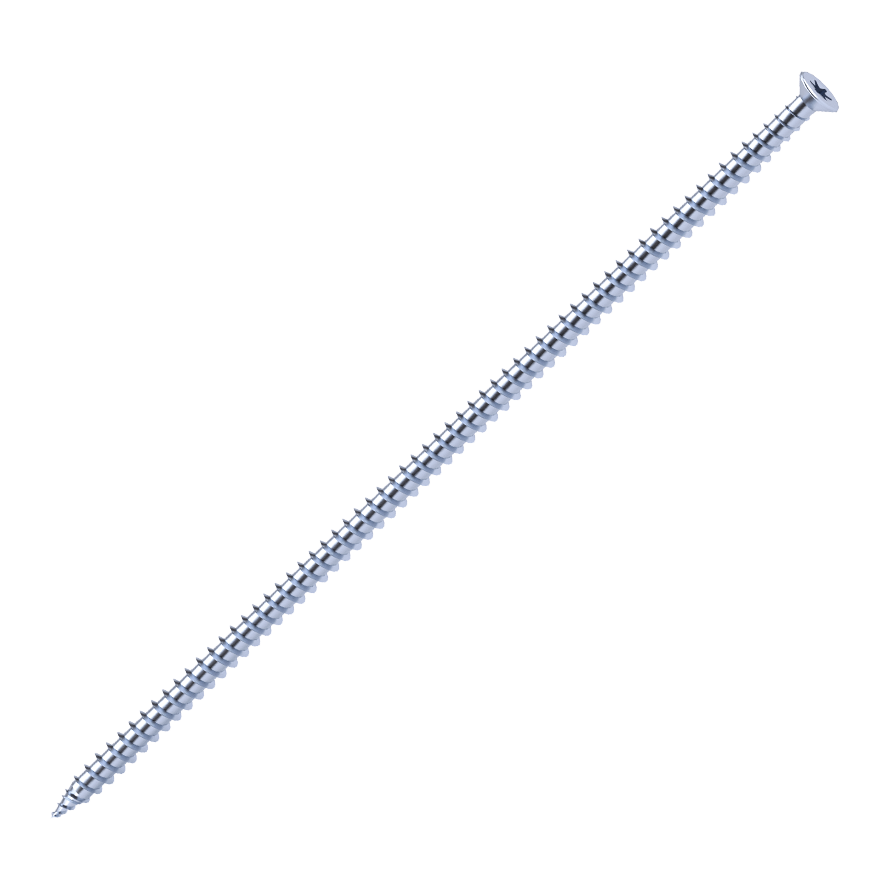

Fully threaded screws

With SIHGA® fully threaded screws, the thread extends over the entire length of the screw, which means that these screws can withstand particularly large tensile and compressive forces both in timber construction and in metal construction.

Partially threaded screws

With partially threaded screws, the thread only extends over part of the screw length. These screws are therefore particularly suitable for fixing wood to wood.

SIHGA® tip: Choose the threadless part so that it is at least equal to the thickness of the plank you want to fix.

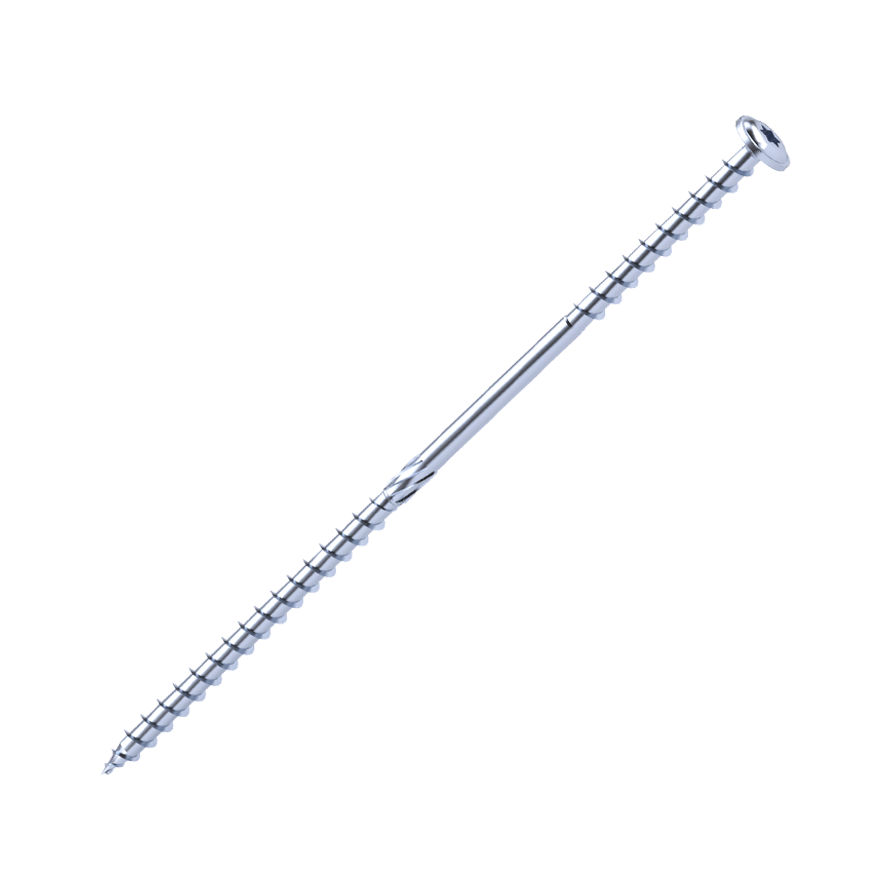

Double-threaded screws

A double-threaded screw has two different threads, which causes the components to be pulled together when the screw is screwed in. Additional components such as a nut are therefore not required. These screws also allow an adjustable and re-releasable connection without damaging the material.

GoFix® screws from SIHGA® for fast and secure assembly

The special thing about the GoFix® series from SIHGA®: the system screws can be installed safely using an impact screwdriver. These screws thus offer maximum flexibility in the choice of screw-in method and a high degree of safety.

Advantages of impact screwdrivers during assembly

Compared to conventional screwdrivers or impulse wrenches, impact screwdrivers offer several advantages:

- They generate only low reaction forces, which means that the strain on the wrist is less.

- No special supports are required, which makes overhead working easier.

- There is no need to change tools if an impact screwdriver has already been used in a previous operation.

- They ensure more effective and time-saving work on the construction site.

Areas of application for SIHGA® system screws

The GoFix® system screws cover different applications on the construction site:

- GoFix® MS II: With this product, SIHGA® offers a system screw for fixing wood to wood, including panel materials. The special multi-stage head reduces the risk of splitting in the wood. Pre-drilling or pre-sinking is therefore not necessary.

- GoFix® S+: This screw is used to fix steel parts to wood. The field of application ranges from hanging wooden ceilings on steel beams to fixing steel brackets on wooden beams.

- GoFix® X+: SIHGA® has developed this product for use in high load-bearing connections. The system screw transmits high tensile, compressive and shear forces and thus fastens even blunt wood joints very quickly.

SIHGA® tip: The GoFix® X+ system case provides you with a practical, complete and mobile combination of setting gauge, beam holder and mounting bracket with all accessories.

SIHGA® wood screw GoFix® MS II

This wood screw meets the highest demands for wood construction. The special thread geometry ensures rapid screw insertion and the multi-stage head ensures a clean and flush screw pattern. The splitting effect in the wood is thus enormously reduced, so that even screw connections in the edge area are possible without any problems. Thanks to the special SIHGA® tip, the system screw can be applied quickly and precisely.

The areas of application for theGoFix® MS II screw are many and varied. The system screw scores points with its flexibility in terms of the screw-in angle, especially when installing sloping roof constructions. Screwing at 0 degrees to 90 degrees to the fibre is permissible. The wood screw can also be used for fixing above-rafter insulation, provided the insulation material used has a compressive stress of over 50 kPa. And with the highest ductility class S3, the screw offers proven safety in earthquake-prone regions.

All accessories, including the SIHGAFIX bit system, Systemstift® and assembly instructions, are included.

SIHGA® tip: For screwing in hardwood without pre-drilling, we recommend the GoFix® SH.

SIHGA® presents both system screws for fixing wood to wood and for joining metal such as steel or aluminium to wood. SIHGA® has developed GoFix® X+ for use with high load-bearing connections.

Usually, system screws have a Torx drive, which allows the screw to be mounted with a simple screwdriver. SIHGA® system screws, however, withstand particularly high loads and can therefore even be installed with an impact screwdriver. This screw-in method makes work much easier and offers the fabricator additional safety.

System screws are usually very resilient and can withstand high loads. However, the exact load capacity values depend on various factors, such as the material used, the size of the screw and the shape. For more information, read the specific product details on the respective product page to ensure that the screws are suitable for the intended application.