YOUR EARLY WARNING SYSTEM FOR MOISTURE INGRESS

MONITORIX® EARLY WARNING SYSTEM FOR MOISTURE INGRESS

With the new Monitorix® moisture monitoring system, SIHGA® has set itself the task of preventing costly moisture damage in timber construction/massive construction. The innovative early detection system is used to monitor moisture and water ingress in timber components and can be integrated both in new buildings and later on in renovation work. The early warning system continuously monitors the moisture content in the roof, walls and floor and sounds the alarm immediately if anything abnormal is detected. This means that countermeasures can be initiated at an early stage and expensive damage caused by moisture ingress can be prevented.

EARLY DETECTION OF MOISTURE INGRESS IN WOODEN COMPONENTS

Free service from SOLUTO (optional upon purchase)

- SOLUTO is also alerted in the event of damage

- Contact within 3 hours

- Assessment of the damage

- Restoration and settlement with insurance

Relocation by SOLUTO is possible at a charge.

Anyone who has damage needs SOLUTO

- Mo-So | 0-24 Uhr | 360 days per year

- Direct settlement with insurance

- Phone: 0800 700 100 - Emergency-Hotline

- More about SOLUTO on www.soluto.cc

Ideal for your first project

- A single-family home can be completely monitored indoors.

- Up to 8 problem areas can be monitored

- Leaks on smaller flat roofs can be pinpointed down to the square meter.

- Only electricity and an internet connection are required

Private customer information: If you require Monitorix for private use, please contact our team at monitoring@sihga.com or +43 7612 74 370 0

RUST-FREE

WATER-RESISTANT

NOT AN ACCELERANT

Innovative early warning system for moisture and water ingress in timber construction/massive construction.

Unobtrusive system that can be easily integrated during construction or renovation

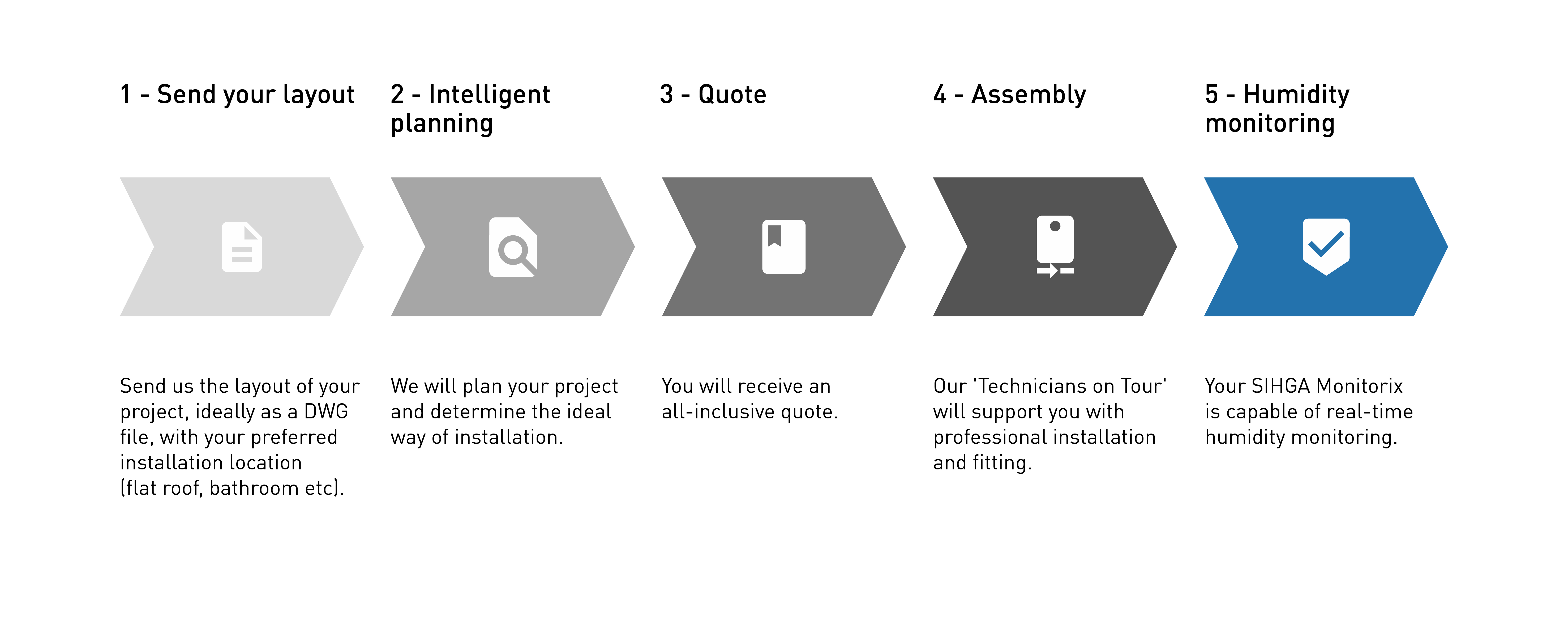

If required, our technicians on tour will support you with professional installation

Report with exact location of the damage

Immediate protection directly after installation and during the entire period of use

Securing the value of real estate in timber construction

Retrofitting also possible (surface-mounted system)

Free planning and dimensioning by our experienced dimensioning specialists

Reliable monitoring of all trades

Lower building insurance premiums: 3 months premium-free on conclusion of contract + 10 per cent additional discount on tap water insurance with Zürich Versicherung

Prevents warranty claims due to moisture

EARLY DETECTION

LEGAL CERTAINTY

RELIABLE CONTROL

Awards

SIHGA® won the Digitalos Award in the category "Digital Transformation" in October 2022 for its Monitorix® system. In November 2022, SIHGA® also took first place in the Upper Austrian Crafts Award of the WKOÖ in the category "Innovation & Digitalisation" for its Monitorix® moisture monitoring system.

At the 17th Industry Day Wood Cologne 2023, we were awarded the Woody Award - 1st place in the "Innovative Product" category for our moisture monitoring system - Monitorix.

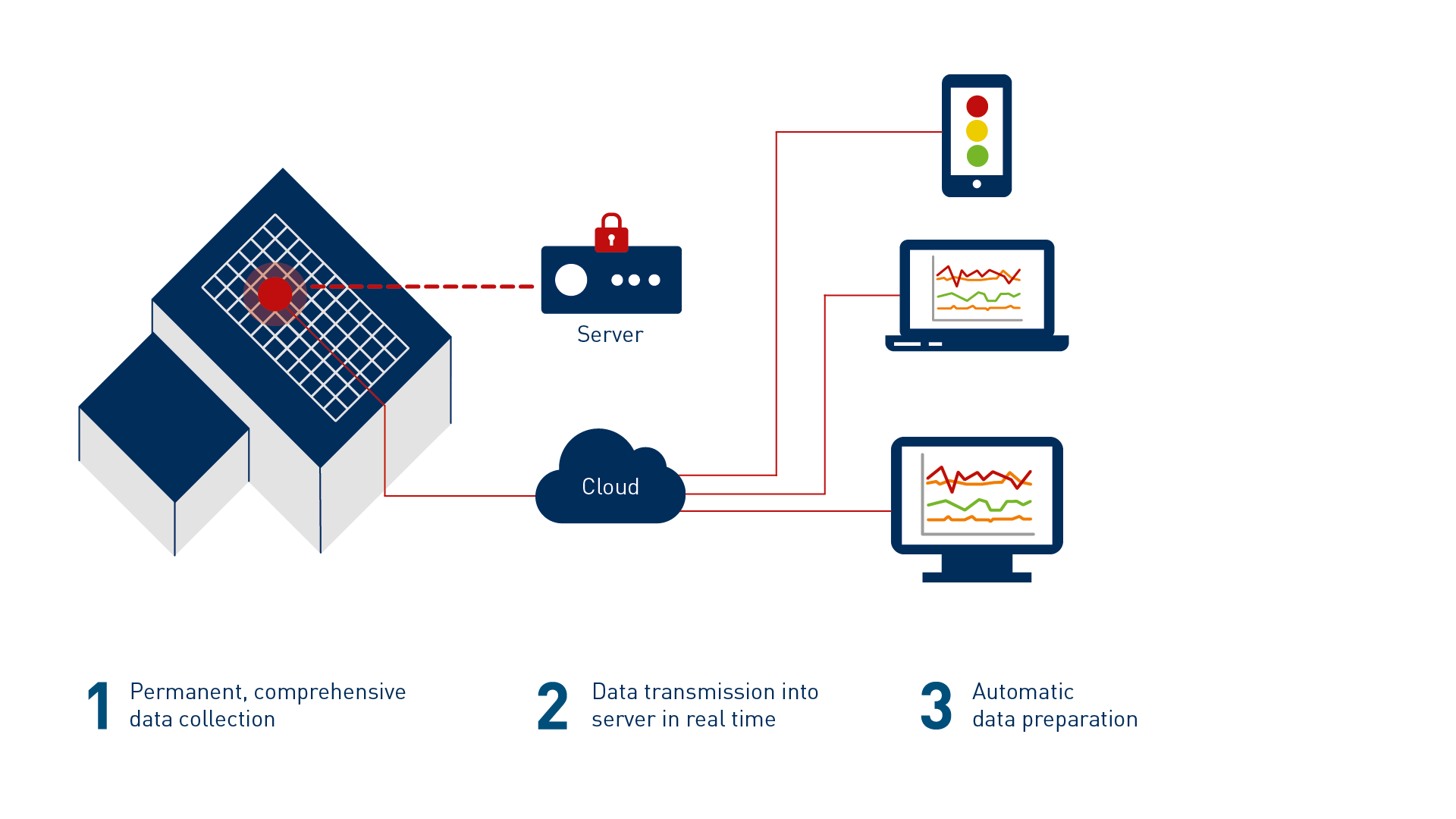

The sensors for the early warning system are installed in the desired area of the building. These send their measured values continuously and in real time to a terminal that is protected in a technical room. This is where the data is evaluated. The owner can immediately see the current status via a traffic light system - in the event of damage, the exact location and time of occurrence of the damage is reported. Detailed, including historical data, can be accessed via a cloud server. With our early detection system, the building is protected from damage due to undetected water ingress directly after commissioning and throughout the entire period of use.

The tests carried out by the OFI have confirmed the functionality of the moisture sensor and its applicability to various insulation materials.

Dr. Paul Pázmándy,

OFI-Expert on adhesive bonding

The sensors were tested in a climate chamber and climate cabinet and exposed to different, sometimes extreme temperatures and humidity levels. There was good agreement between the measured air humidities and the reference sensors of Holzforschung Austria.

Dr. Julia Bachinger,

Expert at Holzforschung Austria

The sensor is resistant to mould and ageing, resistant to the effects of pressure and shear stress and can be used in any climate.

Prof. Dr. Arved C. Hübler,

TU Chemnitz