Visibly fix the facade with SIHGA®

Advantages of visible facade fixing

- shorter installation time

- easy fixing

- long service life

- reduced splitting and cracking

- a clean facade appearance

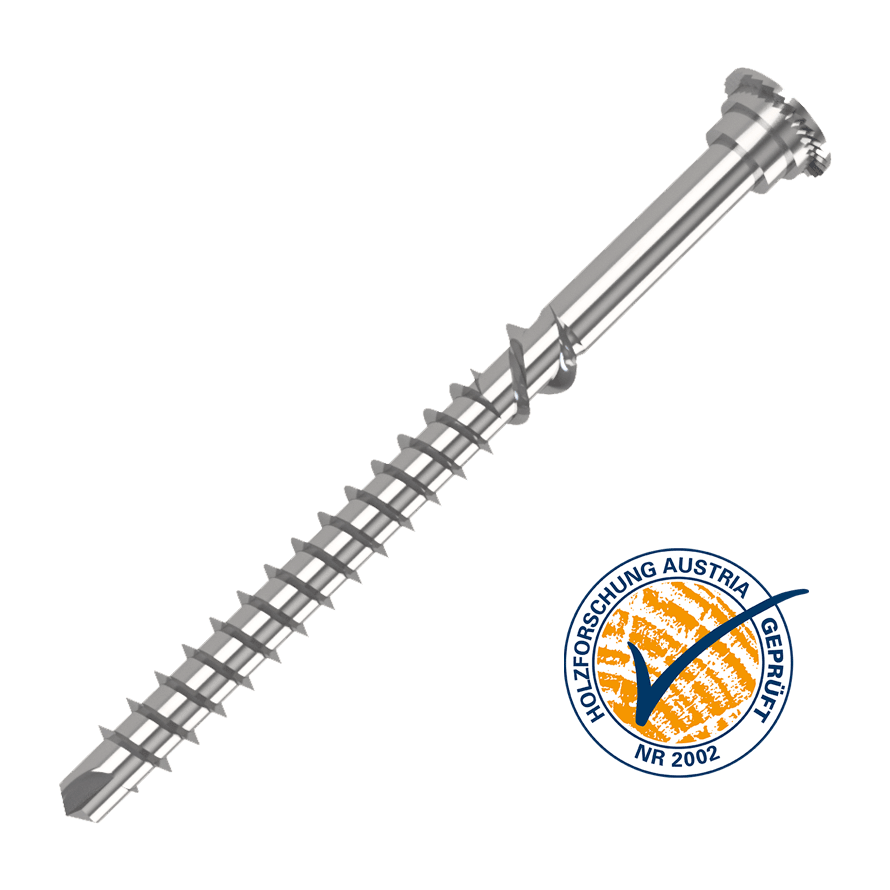

Visible facade fixings with Alu-TeFix®

- Made from high-quality, rust-free stainless steel: These screws are used to fix wood to the TefaFix® F substructure - without pre-drilling or pre-sinking.

- In A2 quality: These screws fix wood to aluminium and are particularly suitable for woods with a high tannin content - also without pre-drilling or countersinking.

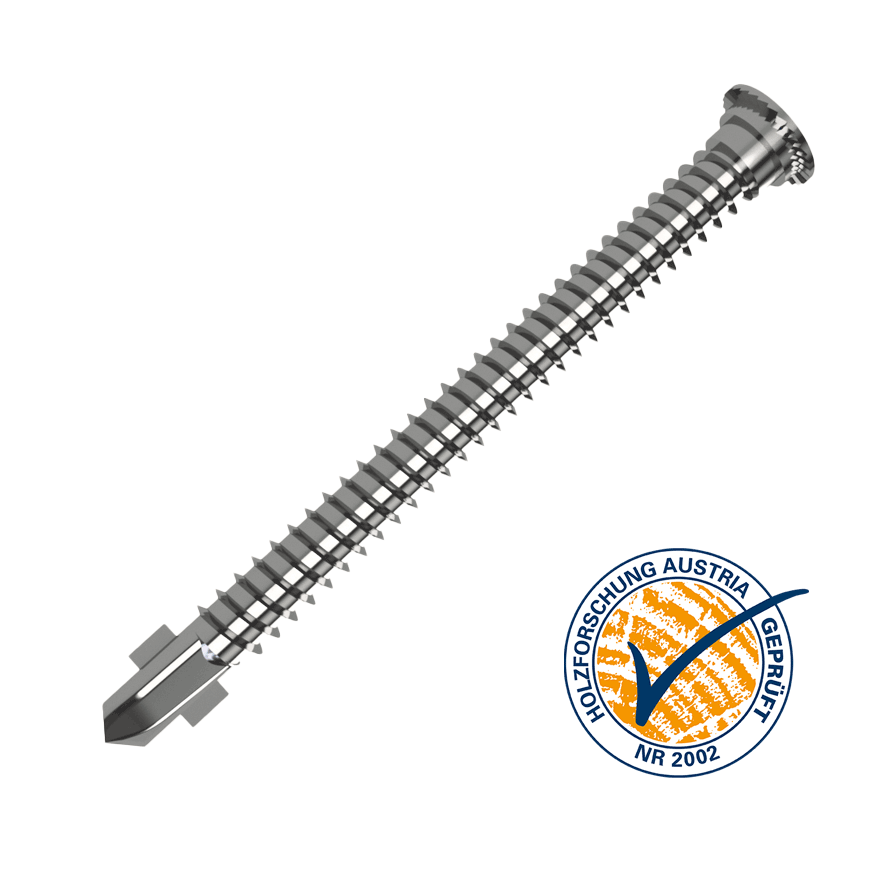

TeFix® for a clean facade appearance

To fix wooden facades to wooden substructures, we recommend the TeFix® stainless steel screw. This is not only rust-free, but also extremely break-resistant and is therefore ideal for outdoor use. As with the other fixing solutions from SIHGA®, no pre-drilling or pre-sinking is needed. The facade panels can be installed easily and cleanly.

The screw's special friction shaft pre-drills the wood and ensures that it can swell and shrink. This reliably prevents cracking and splitting. TeFix® also features a particularly thin, multi-stage head equipped with saw-tooth ribs so that displacement or splintering of the wood is avoided. This makes the screw suitable for almost all softwoods, hardwoods and thermowoods.

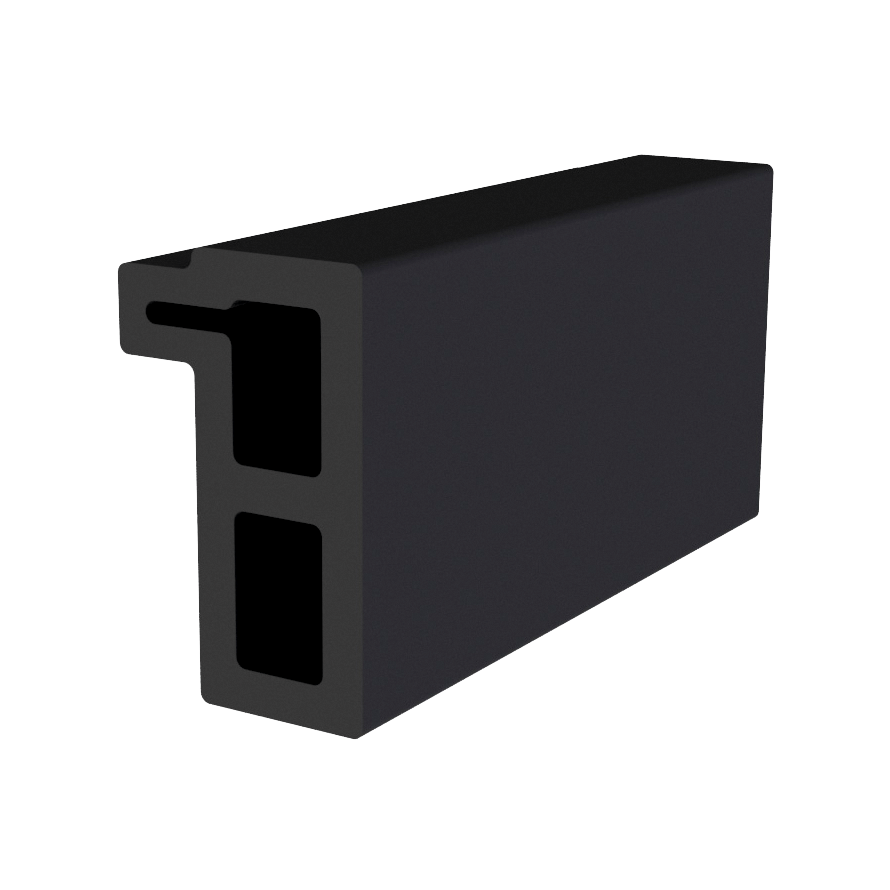

In facade construction, the TeFix® is the tool of choice in combination with our structural wood protection KompeFix®. This product ensures the necessary space between two timbers and thus ensures good ventilation as well as a long service life of the screw and facade.